Paddle Spot Welding Machine For Lithium Battery

-

Descriptions :

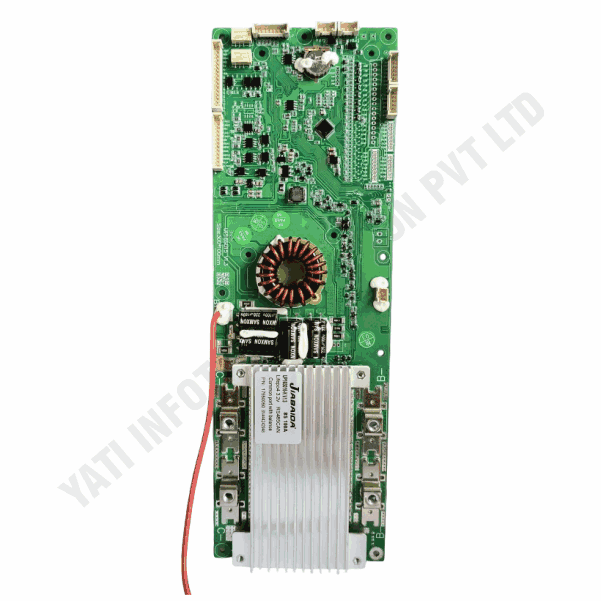

Paddle-Spot Welding Machine

The Spot Welding Machine (Manual) is a versatile, user-operated device designed for joining metal surfaces through localized heat generated by electrical resistance. Primarily, it is used for welding thin metal sheets in industries such as automotive, electronics, and manufacturing. Unlike automated systems, this manual machine requires the operator to apply pressure and control the welding process manually. As a result, it allows for greater precision, especially in small-scale or intricate welding tasks.

Moreover, the machine is equipped with adjustable settings for current and welding time, providing flexibility to accommodate different metal types and thicknesses. Thanks to its compact and straightforward design, it is well-suited for use in tight spaces or delicate welding jobs. In addition, the simple operation makes it accessible even for smaller workshops or repair environments.

Despite its simplicity, the machine delivers reliable and consistent weld quality, making it a practical and cost-effective choice for professionals and hobbyists alike. Ultimately, this manual spot welding machine is ideal for custom welding projects, repairs, and low-volume production where precision and control are essential.

-

Key Features & Specifications:

-

Welding Type: Resistance paddle-spot welding

-

Input Voltage: AC 220V, 50/60Hz

-

Welding Current: Up to 8000A (adjustable)

-

Pulse Control: Single, double, or multi-pulse

-

Material Support: Nickel, copper, and nickel-plated steel

-

Welding Thickness: 0.1mm – 0.3mm

-

Operation Mode: Foot-pedal trigger

-

Cooling System: Air-cooled or optional water-cooled

-

Application: Lithium battery pack welding (18650, 21700, LiFePO₄)

In conclusion, the Paddle-Spot Welding Machine delivers speed, precision, and reliability—making it a top choice for professionals involved in lithium battery assembly.

-

-